Steel columns are used in every construction project, from small residential to big industrial and high-rise buildings. These vertical members transfer gravity loads—dead, live, wind, even dynamic crane impacts—from beams, slabs and roofs into the foundation, keeping the structure intact under all conditions. Beyond strength, steel columns offer versatility in shape, cross section, thickness and material combinations (including concrete-filled composites) to achieve efficient, slender designs that reduce foundation requirements and speed up construction. Prefabrication, precise base plate detailing and advanced digital coordination (BIM) streamline installation, cut waste and improve long-term performance.

What Is a Steel Column? Understanding Its Structural Role

A steel column is a vertical structural element designed mainly for compressive load-bearing, transferring forces from superstructure elements into the foundation. Key functions include:

Axial Load Transfer & Support

Steel columns manage the full range of axial forces and building loads—permanent (dead), variable (live), lateral (wind, seismic), and even dynamic (crane impact, machinery vibrations). Their high yield strength (typically 50 ksi for ASTM A992/A500) and elastic modulus (~29,000 ksi) means minimal deflection under service loads.

Lateral Stability & Frame Action

When part of a rigid frame or braced system, columns resist bending moments and shear forces, keeping building drift limits and occupant comfort. This dual role is the foundation of structural integrity in high-rise buildings and multi-story frames.

Foundation Load Reduction

Thanks to steel’s high strength-to-weight ratio, columns can be slender, concentrating loads into smaller footprints. This reduces excavation volumes and concrete foundation sizes, providing numerous advantages by saving costs.

Construction Efficiency

Modern construction uses off-site fabrication of hot-rolled sections (wide-flange, HSS) or welded box columns, complete with base plates, leveling shims and anchor holes. On-site installation is just bolting and grouting, reducing labor hours and schedule risks.

Sustainability & Durability

Steel is infinitely recyclable, enhancing sustainability & durability, and galvanized steel options add corrosion resistance for coastal or chemical environments. Fireproofing with intumescent paints or concrete-encased composites ensures fire resistance without bulk.

Through these roles, steel columns are the backbone of resilient, adaptable and eco-friendly construction.

Structural Steel Column Types and Applications

| Structural Steel Column Type | Structural Steel Column Characteristics | Structural Steel Column Typical Use Cases |

|---|---|---|

| Wide Flange (W-section) | High moment of inertia about major axis; parallel flange faces; thick plates | High-rise buildings, bridges, heavy industrial |

| Hollow Structural Sections (HSS) | Square/rectangular tubes; uniform cross section; excellent torsional strength | Exposed architectural columns, seismic structures |

| Box Columns | Welded steel plates; can be concrete-filled; high rigidity | Tall skyscrapers (perimeter systems), façades |

| Pipe Columns (CHS) | Circular hollow sections; high buckling resistance | Parking structures, pedestrian bridges |

| Steel-Concrete Composite | Steel tube filled with concrete; superior axial capacity & fire resistance | High-rise cores, seismic zones |

Wide-Flange (W) & Universal Columns

Wide-flange sections (W–shapes in the US; universal columns or UC in Europe/India) are the most common types of structural steel columns due to their favorable dimensions :

- High moment of inertia (I) delivered by broad, parallel flanges, resisting bending across the major axis.

- Standardized dimensions (e.g., W8×10 through W14×500) that simplify procurement and design.

- Load-bearing capacity suitable for both axial loads and combined axial-bending scenarios.

Applications:

- Interior and perimeter supports in high-rise buildings, placing columns at bay centers.

- Bridge piers, off-shore platforms, and parking garages where axial and lateral demands coexist.

| Section | Area (in²) | I (moment of inertia of cross-section, in⁴) | Weight (lb/ft) |

|---|---|---|---|

| W8×10 | 2.94 | 45.8 | 10 |

| W12×65 | 19.2 | 1,060 | 65 |

| W14×370 | 98.8 | 22,800 | 370 |

This configuration offers efficient steel usage for primary gravity columns and moment-resisting frames.

Hollow Structural Sections (HSS)

Hollow Structural Sections—square, rectangular, or circular—are made by welding plate edges, creating a closed geometry renowned for:

- Uniform buckling resistance: High radii of gyration ensure balanced performance under axial and lateral loads.

- Torsional rigidity: Closed-section resists twisting, suited to corner columns or cantilevers.

- Aesthetic quality: Smooth, exposed surfaces ideal for architectural showcases without visible welds.Typical grades: ASTM A500 Grade B/C (US), IS 4923:2014 (India).

Applications:

- Exposed columns in atriums, malls and facades.

- Long span truss nodes and canopy supports.

- Pedestrian and cycle bridges where profile cleanliness matters.

Box & Pipe Columns

Box columns are built-up by welding four plates into rectangular tubes; pipe columns use circular HSS or seamless pipe. They offer:

- Box Columns:

- High flexural and torsional stiffness for building cores and outriggers in tall structures.

- Internal voids for electrical and HVAC services, reducing space requirements.

- Concrete infill turns them into composite columns with higher axial capacity and fire resistance.

- Pipe Columns:

- Uniform buckling capacity about any axis, ideal for slender, minimal-footprint supports like streetlights or sign poles.

- Easy formwork integration for composite action when concrete-filled.

Applications: Core and perimeter frames in skyscrapers, canopy and signage supports, slender structural accents.

Composite & Special-Shape Columns

Combining steel and concrete creates composite columns with combined strengths:

- Concrete-Filled Steel Tubes (CFST):

- High axial capacity, ductility and seismic resilience without additional fireproofing.

- Used in supertall buildings like the Shanghai Tower’s megacore.

- Tied & Spiral Columns:

- Internal steel ties or spiral reinforcement around concrete cores, enhancing confinement and energy dissipation.

- Ideal for seismic zones requiring ductile behavior.

- Custom Shapes (L-shaped, circular, tapered):

- Meet architectural or spatial requirements—L-shapes stabilize building corners, tapered sections optimize material use at transitions.

These configurations address unique load transfer, buckling and aesthetic demands in special projects.

Universal Columns and Fixed-Length Columns

- Universal Columns have wide flange geometry in standard depths and weights—ideal for general use in residential and commercial buildings.

- Fixed-length Columns are pre-cut and drilled, for rapid erection where exact heights are known (e.g. modular construction).

Steel Columns in High-Rise & Industrial Structures: Why They Matter

Steel columns are indispensable in high-rise buildings, industrial facilities, and residential projects. Their unmatched strength-to-weight ratio enables tall, slender frames and vast clear spans.

In high-rise buildings, steel columns enable reduced structural depth and lighter weight per floor:

- Strength-to-weight ratio: Slender columns carry gravity loads while resisting drift under wind and seismic actions.

- Ductility: Controlled yielding under extreme loads ensures life safety and limits permanent drift.

- Core & perimeter tube systems: Innovations like bundled tubes and diagrid frames rely on steel columns to form rigid, cantilevered skins that handle lateral forces efficiently.

Naberezhnaya Tower (Moscow) uses built-up box perimeter columns for vertical loads only, with outriggers to tie into a stronger core for lateral stability.

In industrial facilities, steel columns face heavy, dynamic demands:

- Overhead crane support: H-shapes sized and detailed per CMAA/AIST for vertical impact and lateral thrust loads.

- Portal frames (>30 m spans): Clear-span design maximizes unobstructed workspace, from warehouses to aircraft hangars, using tapered columns to optimize steel distribution.

- Corrosion resistance: Stainless or alloy steels for marine or chemical environments, galvanizing and multi-layer coatings (zinc-epoxy-urethane) for rust protection.

Steel columns’ rapid prefabrication and bolted connections mean safer, faster erection—essential in projects with tight schedules or hazardous environments that explore innovative construction method .

Essentials of Steel Column Design: Load, Size, Shape & Standards

Load Considerations

Designing a structural steel column requires considering:

- Dead Loads: Self-weight of steel, fixed equipment, finishes.

- Live Loads: Variable occupancy, furniture, vehicle weights per ASCE 7/IS 875.

- Wind & Seismic Forces: Lateral pressures and inertial loads induce bending and shear demands.

- Dynamic/Impact Loads: Crane wheel loads, vertical impacts, and fatigue cycles in industrial settings.

Comprehensive load combinations ensure the column resists worst-case scenarios without exceeding service deflections or strength limits.

Cross Section, Slenderness & Buckling

Preliminary Sizing often follows rules of thumb:

- Width-to-thickness ratio ~12:1 for flanges or walls to avoid local buckling.

- Height-to-width ratio ~3–5:1 for balanced stiffness and economy.

Slenderness Ratio (λ = KL/r) governs buckling risk:

| Classification | λ Range | Governing Failure Mode |

|---|---|---|

| Short Columns | λ < 50 | Yielding predominates |

| Intermediate Columns | 50 ≤ λ ≤ 200 | Combined yield & buckling analysis |

| Slender Columns | λ > 200 | Euler buckling controls |

Effective length factor (K) depends on end-conditions (pinned, fixed, free). Cross-section selection balances axial capacity (A⋅Fy) and buckling strength (π²EI/(KL)²).

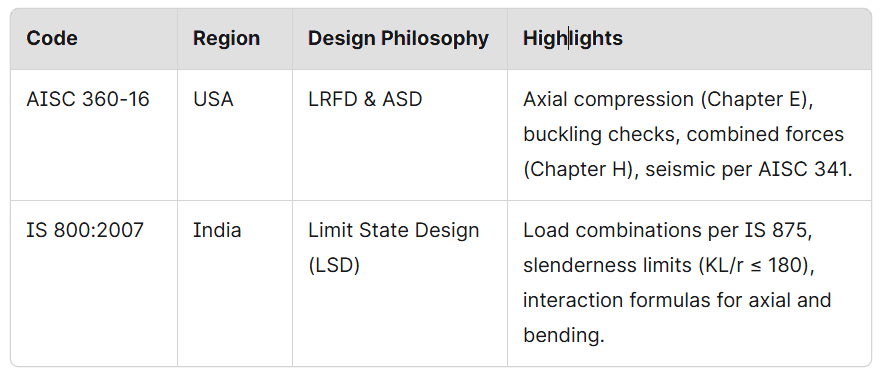

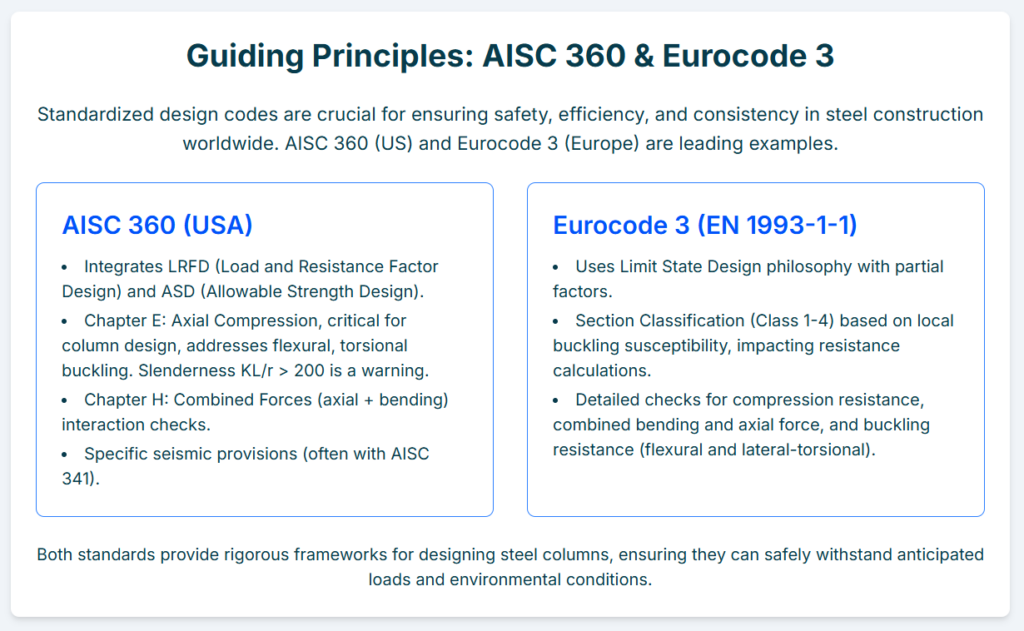

Design Standards

- AISC 360-16 (US): LRFD/ASD methodologies; chapters on axial compression (E3), flexure (F2), shear (G2), and combined loading (H1).

- IS 800:2007 (India): Specifies limit state design; slenderness limits (KL/r ≤ 180 for gravity columns) and interaction checks.

- Eurocode 3 (EN 1993-1-1): Classifies sections (Class 1–4) by local buckling; uses partial factors for ultimate limit state design.

Steel column design balances safety factors, serviceability requirements and economic efficiency, often using structural analysis software for iterative optimization.

Design Considerations

When specifying a steel column with base plate, consider:

- Base Plate Design: Thickness and size to distribute loads into concrete; governed by AISC 14.7 or IS 800 guidelines.

- Anchor Bolt Layout: Bolt diameter, length and edge distances to prevent concrete breakout under tension.

- Installation Shims & Grout: Leveling plates ensure accurate height adjustment; non-shrink grout transfers load evenly.

- Corrosion & Fire Protection:

- Galvanized steel or intumescent paint protects against rust.

- Concrete encasement or fireproofing ensures fire resistance per ASTM E119/IS 401.

Other factors:

- Erection sequencing to avoid overloading temporary supports.

- Weld details and inspection plans for built-up sections.

Role of BIM in Steel Column Design & Installation

BIM has changed the way steel columns are designed, detailed, fabricated and erected:

- Dimensionally Accurate Models: 3D digital twins capture every shape, length and base-plate hole pattern. Fabrication data and erection plans derive directly, eliminating manual drafting errors. Revit and Tekla Structures create 3D models with embedded section properties, connection details and base plate geometries, eliminating drafting errors and ensuring precise steel column with base plate layouts.

- Parametric Coordination: One edit—such as column height—updates related elements: anchor bolt schedules, grout thickness, splices and shop drawings.

- Clash Detection: Automated conflict checks identify where columns intersect MEP ducts, beams or architectural features. Early resolution in the model prevents on-site rework which accounts for 6.4 % of direct construction costs on average.

- Rework Cost Reduction: Studies show BIM can reduce rework costs by nearly 49 %, saving millions on large projects by minimizing RFIs and field revisions.

- Automated Fabrication Outputs: Software like Tekla Structures and SDS/2 generates NC files, DXF exports and connection details—ensuring steel components fit precisely without manual redrawing.

- Accurate Quantity Take-Offs: BIM produces material lists for columns, plates, anchors and weld consumables, cutting waste and over-ordering by up to 15 %.

- Lifecycle Management: As-built BIM models serve facility managers for maintenance, retrofits or expansions—preserving column configuration, load capacities and fireproofing details for decades.

By uniting structural, architectural and MEP disciplines, BIM turns steel column workflows into a collaborative, data-driven process, ensuring safer, faster and more efficient constructions.

Conclusion

Steel columns are the vertical backbone of modern construction, enabling slender high-rise towers, vast industrial spans, and sustainable, recyclable frameworks. Their design combines advanced material science, precise calculations for buckling and loads, international standards, specifications, and BIM workflows. By understanding the types, design essentials, and digital coordination, engineers and architects can create robust, efficient structures that last for decades.

Book your Demo with BuildTwin Success AdvisorFrequently Asked Questions

What is involved in steel column design?

Steel column design involves selecting the appropriate cross-section, size, and material grade based on load requirements, slenderness ratios, buckling resistance, and compliance with design standards such as AISC 360-16 or IS 800:2007.

How does BIM technology improve steel column design and installation?

Building Information Modeling (BIM) enables dimensionally accurate 3D models of steel columns, including base plate details, anchor bolts, and connection geometry. BIM streamlines fabrication, reduces drafting errors, supports clash detection, and facilitates efficient installation, ultimately reducing rework and project costs

How does a steel column with a base plate function in a building?

A steel column with base plate distributes the loads from the column into the concrete foundation. The base plate is designed for adequate thickness and size to spread the load, and it is anchored with bolts to prevent movement.

How do shop drawings differ from construction drawings?

Construction drawings provide the overall design and intent, while shop drawings focus on the specific details needed for fabrication and installation. Shop drawings often include information not found in the original design documents, such as connection details and material specifications