Introduction

A precast concrete plant comes alive when every part – from slabs to sandwich wall panels – is digital, so decisions can be made instantly. Digital twin is not a buzzword here; it’s how structures, materials and workflows are mirrored in real time, making precast concrete building components living systems. This article explains how digital twin reshapes precast concrete wall construction, precast detailing services and the manufacturing process for precast concrete panel manufacturers.

What Is Digital Twin Technology in Precast Concrete?

Digital twin means creating a virtual counterpart for physical precast panels, walls, columns and slabs, along with the machines and workflows that produce them. These twins are monitored and updated through sensor data – thermal performance, curing, structural integrity and workflow efficiency. The digital model runs in parallel with precast concrete manufacturing to improve precast concrete building construction quality.

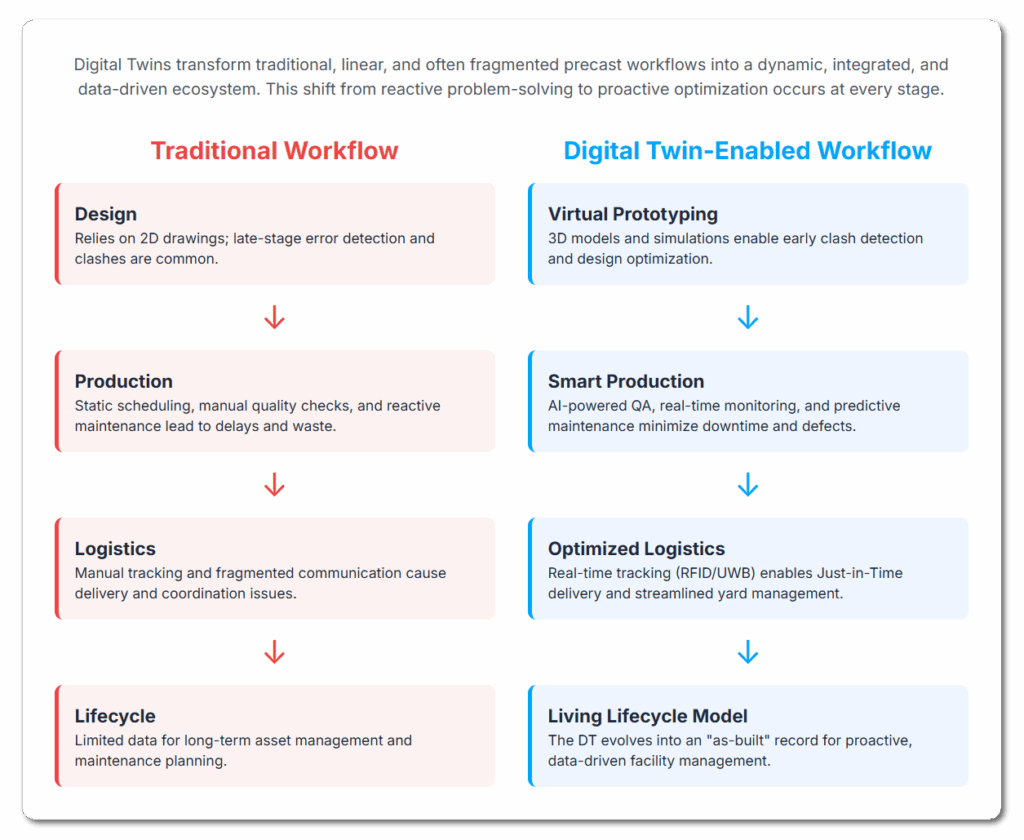

How Digital Twins Transform Precast Concrete Manufacturing

Quality Control in Precast Concrete Wall Construction

- Real-time AI driven inspection of precast concrete wall panels checks dimensional accuracy, surface finish and embedded details (like inserts or embeds) before panels leave the controlled environment.

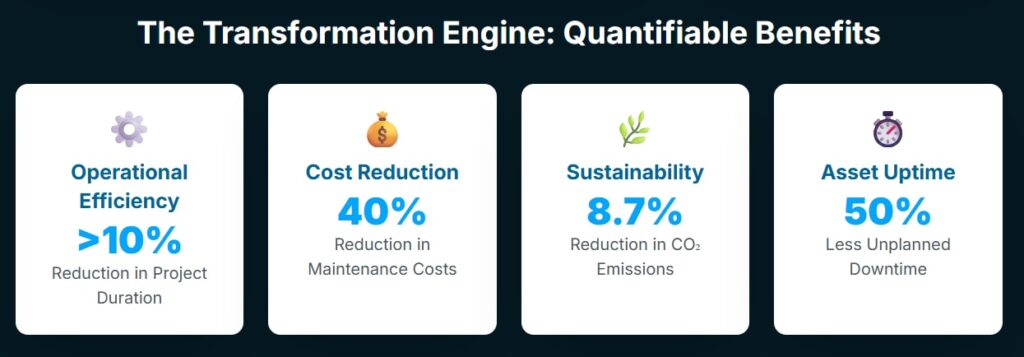

- AI vision and analytic algorithms flag deviations instantly, reduce rework and ensure structural soundness. One study shows up to 10% reduction in project duration and 40% cut in maintenance costs thanks to quality gains.

Production of Precast Panels

- By capturing curing curves and thermal performance through sensors in precast products – e.g. sandwich wall panels – digital twins optimize the cure schedule for faster strength gain and energy savings.

- This way you can reach design compressive strength earlier with less energy use, faster installation and cost effectiveness.

Precast Detailing Services and Design Flexibility

- Architects and engineers use a collaborative digital twin platform for precast detailing services, to adapt wall panel shapes, embedded elements, insulation details (e.g. expanded polystyrene or extruded polystyrene layers), and finishes.

- A digital twin allows simulations for thermal insulation (R-values), form changes, attaching architectural panels and customizing finishes – all before production starts.

- Using BuildTwin, teams can access specialized precast detailing services and collaborate with vetted vendors globally, reducing delays while maintaining quality and compliance.

Workflow and Project Timelines

- The manufacturing process becomes transparent when every pallet, panel and component is tracked with RFID or UWB, feeding data into the digital twin. Inventory, deliveries, workflows and job-site handling sync seamlessly.

- Report shows a roughly 50% reduction in downtime, 30% improvement in labor efficiency and on-time delivery gains by automating yard layout and JIT delivery through digital twin systems.

Technical Components and Integration

Sensors, Data, and Modeling

Digital twin technology runs on data capture:

- Sensor types: temperature sensors in curing beds, embedded stress strain sensors, vibration or machine health monitors, RFID/UWB trackers on panel rigs.

- Data flow: collected data updates the digital model continuously – creating a linked system that reflects real-time conditions of precast products, production lines and machinery.

Simulation and Predictive Analytics

The twin simulates:

- Concrete strength evolution, estimating time to reach critical compressive strengths.

- Lifecycle maintenance, forecasting wear in mold form components or handling cranes.

- Workflow scenarios, allowing planners to test “what-if” scheduling, resource allocation and tackle bottlenecks in slabs, walls or columns.

Workflow Integration: BIM, MES, ERP

- Models are connected to BIM tools (Revit, Tekla), MES and ERP systems – ensuring precast concrete building construction aligns with design, production and budget tracking.

- This tech stack supports precast concrete wall systems production with minimal friction and maximum traceability.

| Benefit | Impact |

|---|---|

| Predictive quality assurance | Fewer rejects, higher structural reliability in precast concrete panels |

| Accelerated production | Faster curing and cycle times, leading to reduced project timelines |

| Workflow efficiency | Less downtime, better labor use, precise inventory tracking |

| Design flexibility | Realistic simulation of wall panel forms, finishes, insulation layers and thermal performance |

| Cost effectiveness | Energy savings, less rework, fewer maintenance events |

Limitations:

- Implementation cost – requires sensor investment, integration with BIM/MES/ERP and staff training.

- Data standards and interoperability are fragmented among vendors.

- Skilled staff needed to interpret dashboards and manage models.

The reports suggest a phased approach: start with one value twin (e.g. curing or quality) and then expand across plant functions.

Platforms like BuildTwin address these hurdles with automated QC, predictive scheduling, and vendor pre-qualification, enabling firms to adopt digital twin workflows without overwhelming complexity.

Use Cases

Commercial building panels: A plant producing exterior precast walls for apartment buildings gains faster installation and continuous insulation efficiency through digital twins optimizing form, finish and cure.

Parking structures and bridges: These require structural integrity, clear detailing and thermal resilience. Digital twins enable reliable production of prestressed concrete beams, columns, slabs and load-bearing wall panels.

Office building facades: Architectural precast products benefit from the ability to preview finishes, integrate materials like brick, sandblasted art or insulation within the digital twin to ensure performance and aesthetics before manufacturing.

Conclusion

Digital twin technology changes how precast concrete building construction works – linking every stage from precast detailing services and precast concrete wall construction to precast concrete panel manufacturers optimizing workflows. By mirroring physical assets – walls, panels, slabs, columns and production – and simulating performance in a controlled environment, the industry gets better quality control, design flexibility, efficiency, cost savings and shorter project timelines. Real pilot data shows double-digit gains and major maintenance and labor savings. The way forward is modular implementation, integration with BIM/MES/ERP and expanding twin capabilities from quality to logistics. As precast walls and structural components drive modern construction, digital twins are the blueprint for smarter, faster and more reliable manufacturing.

To explore how these ideas translate into real-world project execution, check BuildTwin — a global marketplace and ERP platform that streamlines precast detailing, quality management, and vendor collaboration for the AEC industry.