Introduction

Building Information Modeling (BIM) thrives on clarity. Without a defined bim level of development, stakeholders risk misreading model elements, leading to coordination errors, cost overruns, or rework. Adopting a lod framework ensures every team member—from design managers to contractors—knows exactly what each component represents and how reliable it is. This article delivers an expert-level dive into bim model lod, revealing how structured level of development lod practices drive accuracy, efficiency, and lifecycle value for construction projects across the aec industry.

What is BIM LOD and Why It Matters?

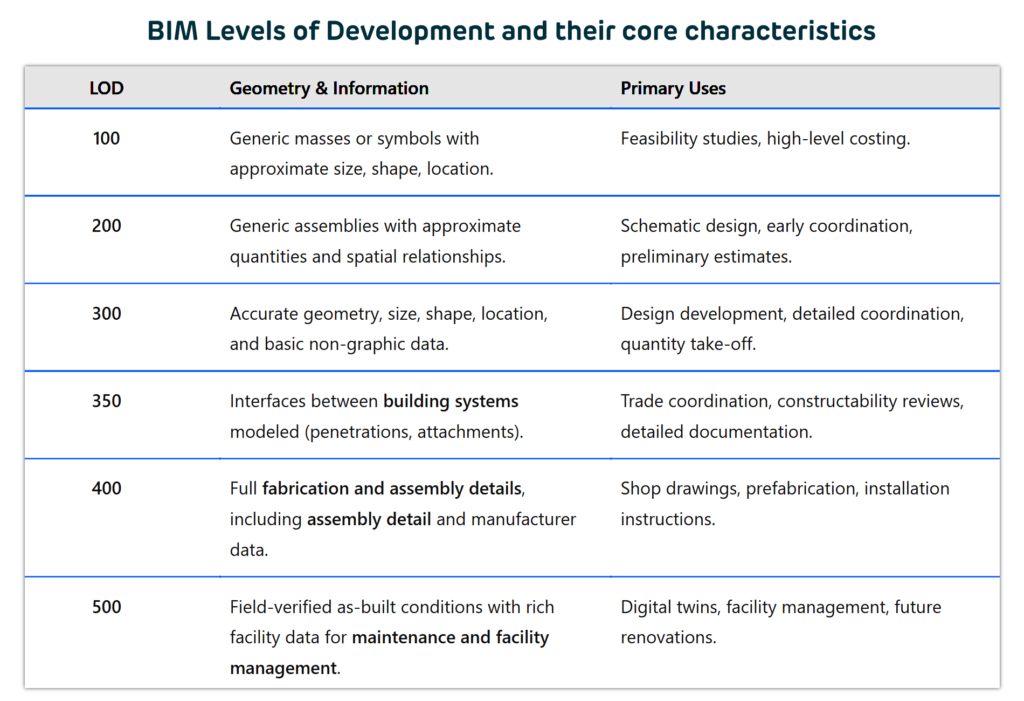

LOD, or Level of Development (sometimes referred to as Level of Detail), is a set of specifications that defines the completeness and reliability of BIM elements at different stages of a project lifecycle. It’s a set of rules that outlines how much detail and what type of detailed information model elements should contain as they move through different project stages from conceptual design to construction and finally to maintenance and facility management.

At its core, LOD answers two questions:

- What geometry and data are present?

- How much can you trust it?

Without these definitions, a contractor might mistake a placeholder wall for a final detailed design element, or a facility manager might lack the metadata needed for effective facility management. In short, LOD is the backbone of design and construction process transparency, underpinning everything from early approximate quantities to final exact specifications, facilitating construction coordination.

Why does it matter?

Clear Communication & Collaboration: LOD provides a common language for all project stakeholders (architects, engineers, contractors, owners). This clarity reduces misunderstandings and ensures all project participants are on the same page about the model’s reliability and usability at any given stage, ultimately leading to efficient project execution .

Project Accuracy: By defining the expected accuracy and content of model elements, LOD reduces errors, omissions and rework. This structured approach to detailed design lod information development is key to overall project accuracy.

Risk Management: Early identification of potential clashes and issues is possible with well defined LODs, reducing risks and costly changes during construction.

Resource Allocation: LOD allows teams to focus on developing detailed models only when necessary, optimizing time and resources. Not all elements need to be modeled to the highest level of detail, including fabrication and assembly details, at every stage.

Decision Making: With a clear understanding of the model’s maturity, including future content estimated cost stakeholders can make more informed and timely decisions throughout the project.

LOD Modeling: A Structured Approach to Project Accuracy

A robust bim model LOD framework aligns modeling effort with different project phases. Starting at LOD 100, where conceptual design masses convey basic area, height, and orientation, each subsequent bim level of development layer adds precise geometry, intricate details metadata, and fabrication detail. A clear lod framework emerges from the BIM Execution Plan, where an LOD matrix maps each model element to its required bim lod at each milestone, aiding in construction documentation lod.

Advantages of this structured approach include:

- Aligned Effort & Expectations 🚀

Long‐form bullet: Teams avoid wasted effort by focusing on the right elements at the right time. Early phases use generic building masses for feasibility studies, while later phases layer in precise geometry, assembly detail, and metadata for downstream uses. - Early Clash Detection 🔍

Long‐form bullet: With bim lod definitions, architects, engineers, and MEP trades model at lod 300 or higher just in time to uncover interferences. This mitigates risk, reduces rework, and keeps construction sequencing on schedule. - Data-Driven Cost Estimation 📊

Long‐form bullet: Quantity take-offs at lod 300 enable reliable cost estimation by extracting accurate volumes, areas, and counts from the model. Early cost validation at different stages supports budget compliance and value engineering.

This phased approach turns the design and construction process into a predictable, measurable progression—everyone stays on the same page, and model deliverables drive decision-making with clarity and confidence.

The Journey Through LOD: 300, 400 and 500

Let’s look at the critical stages of LOD 300, LOD 400 and LOD 500 which are key milestones in the design and construction process.

LOD 300 in BIM: The Design Development Stage

LOD 300 is the workhorse of design development, representing every model element with accurate size, shape, location, and orientation—enough to generate reliable construction documents and perform robust coordination.

- Precise Geometry: Elements have accurate and specific dimensions, allowing for detailed analysis and coordination. Provides clear visual representation for stakeholder reviews and approvals.

- Clash Detection & Coordination: Enables detailed clash detection and coordination between architectural, structural and MEP (Mechanical, Electrical and Plumbing) systems. For example, ensuring ductwork (MEP) doesn’t clash with structural beams.

- Construction Documentation: Drawings derived from LOD 300 models are trusted for permit applications and bid packages, reflecting true design intent. LOD 300 models are suitable for generating construction documents, including drawings, sections and schedules. For example, a specific type of wall with its defined layers, thickness and material properties would be modeled.

- Accurate Quantity Take-offs & Cost Estimation: With precise geometry, quantity take-offs at this level yield more accurate estimates, and 4D simulations inform phasing plans.

When to use LOD 300:

- Detailed design validation

- Regulatory plan checks

- Bid package preparation

What LOD 300 doesn’t include is fabrication-specific details such as bolt hole patterns or weld preparations

In a commercial building project, at LOD 300, a specific air handling unit (AHU) would be modeled with its actual dimensions, required clearances and major connection points. This allows for spatial coordination with other building systems and accurate representation in construction drawings. Similarly, structural steel members would be modeled with their precise profiles and locations.

LOD 400 in BIM: Construction-Ready Detail

LOD 400 takes it a step further, focusing on precise details . Model elements at this level are modeled with sufficient detail and accuracy for fabrication, elements are detailed with all fabrication and installation data—bolt holes, weld plates, hanger assemblies, and manufacturer part numbers—so quantities and dimensions can be measured directly for shop drawing generation LOD 400 in BIM means a construction-ready model.

Key Characteristics & Applications of LOD 400:

- Fabrication & Assembly Information: Contains all necessary details for a fabricator to make the component or for a contractor to assemble and install it. This includes precise modeling of connections, supports and sequencing.

- Shop Drawings: LOD 400 models can be used to generate detailed shop drawings for various trades.

- Prefabrication: Essential for projects that utilize prefabrication, as it provides the exact specifications needed to manufacture components off-site. For example, prefabricated wall panels or complex MEP modules would be modeled to LOD 400.

- Reduced On-site Issues: The high level of detail helps in identifying and resolving potential installation issues before they occur on site, minimizing rework and delays.

- Detailed Sequencing and Planning: Supports detailed construction sequencing and installation planning.

Walter P Moore’s high-rise core project reached LOD 400 for critical shear walls. The virtual model exposed rebar clashes, enabling design adjustments that averted costly on-site fixe. Similarly, a stadium’s architecturally significant steel trusses were modeled at lod 400, guiding fabricators with exact bolt patterns and weld details, and cutting three months from the erection schedule.

LOD 400 ideal for:

- Shop-drawing production

- Prefabrication & modular construction

- Complex or exposed structural elements

LOD 500 in BIM: As-Built and Facility Management

LOD 500 represents the building elements as they have been constructed – an “as-built” representation. Model geometry is updated to reflect field-verified conditions, and every asset gains rich metadata: serial numbers, warranties, O&M manuals, and maintenance schedules for seamless facility management. Non-graphic information is updated to reflect the installed conditions and often includes data crucial for operations and maintenance.

Key Characteristics & Applications of LOD 500:

- Field Verified: All information is verified against the actual constructed conditions. This might involve site surveys or laser scanning to capture any deviations from the original design.

- Facility Management: The primary application of LOD 500 is for facility management. The model becomes a rich database of building components, including manufacturer details, warranty information, maintenance schedules and operational data.

- Operations & Maintenance: Facility managers can use the LOD 500 model to locate components, access relevant information for repairs, plan maintenance activities and manage building assets throughout their lifecycle.

- Renovations and Retrofits: Provides an accurate baseline model for future renovation or retrofit projects.

- Digital Twin Creation: An LOD 500 model often serves as the foundation for creating a digital twin of the facility, enabling real-time performance monitoring and management.

BIM LOD Applications & Examples Across Industries

While the core principles of BIM LOD are heavily applied in the building construction sector (commercial, residential, institutional), its benefits extend to other industries, including the aec industry :

Infrastructure Projects:

For projects like bridges, tunnels and highways, BIM LOD is used to define the level of detail for structural components, earthworks, drainage systems and utilities. LOD 400 models can be critical for the prefabrication of bridge segments or complex formwork. LOD 500 models can aid in the long-term maintenance and inspection of these critical infrastructure assets.

Industrial Projects:

In sectors like manufacturing plants, power plants and oil & gas facilities, BIM LOD helps manage complex process piping, equipment layouts and structural steel. LOD 400 is crucial for fabricating and installing intricate piping spools and equipment skids. LOD 500 models are invaluable for plant operations, maintenance and future expansion planning, often integrating with asset management systems.

MEP (Mechanical, Electrical, Plumbing) Industry:

Across all types of projects, MEP contractors rely heavily on detailed LOD models. LOD 300 and LOD 350 (a level often used for detailed coordination) are essential for clash detection and coordinated layouts. LOD 400 is used for the fabrication of ductwork, pipe spools and electrical assemblies.

Civil & Infrastructure:

Crossrail London leveraged LOD 300–400 in design and construction, then delivered an LOD 500 as-built digital twin—Laser scanning of stations fed a COBie-compliant model powering maintenance scheduling and capacity upgrades along 100 km of tunnels, including detailed assemblies fabrication .

Structural Engineering:

A bridge retrofit project adopted LOD 400 for steel reinforcements and connections, enabling off-site prefabrication of complex ribs and reducing on-site erection time by 30 % thanks to clash-free assemblies.

Architecture:

For a museum expansion, designers used LOD 300 for overall form and LOD 400 for custom 3D-bent glass panels, coordinating panel framing with structural mullions to preserve architectural intent and avoid field adjustments.

Commercial Buildings:

A mixed-use tower implemented LOD 300 for MEP coordination in congested ceilings, then refined critical riser modules to LOD 400, allowing trades to install prefabricated assemblies with minimal on-site fitting.

Railway & Digital Twin:

In a Jacobs-led survey of railway digital twins, LOD 500 models emerged as foundational for advanced systems management, clarifying information requirements for signaling, tracks, and rolling stock maintenance in a single integrated platform

Why Choose BuildTwin for Your LOD Modeling Needs?

Navigating the complexities of BIM LOD requires expertise and processes. BuildTwin offers comprehensive LOD modeling expert vendor services to fit your project needs. Whether you need precise LOD 300 models for design development, construction-ready LOD 400 models for fabrication or accurate LOD 500 as-built models for facility management, BuildTwin provides:

Access to Specialized Expertise

Tap into a global marketplace of over 10,000 pre-qualified vendors who excel in modeling at every bim level of development, from LOD 300 coordination to LOD 400 fabrication-ready detail and LOD 500 as-built accuracy. Whether you need precise model element geometry for structural steel connections or detailed MEP assemblies, BuildTwin matches project teams with specialists vetted for international standards and tool proficiency (Revit, Tekla, Civil 3D, and more).

AI-Powered Quality Control

Automatically verify that each model element meets your lod specification and compliance requirements. BuildTwin’s AI QC engine cross-references your BIM against regional codes (Eurocode, American, British, Indian, Australian) and flags discrepancies—preventing errors early, cutting review time by up to 60 %, and ensuring your bim lod deliverables align with project milestones.

Scalable for Projects of Any Size

Whether you’re a boutique structural firm seeking LOD 300 coordination or a multinational contractor pursuing LOD 400 prefabrication and LOD 500 digital twins, BuildTwin scales with your needs. Small teams gain competitive agility through fast vendor matching; large enterprises achieve massive cost savings by automating quality checks and vendor management across hundreds of bim projects.

Book your Demo with BuildTwin Success AdvisorFrequently Asked Questions (FAQ)

Why is a clear BIM LOD framework critical for risk management?

A clear BIM LOD framework allows early identification of potential clashes and issues, reducing risks and costly changes during construction. It ensures that each team member knows the reliability and detail of every model element at every stage

How does LOD modeling contribute to cost estimation and resource planning?

LOD modeling enables accurate quantity take-offs and cost estimation, especially at LOD 300 and above. This data-driven approach helps teams validate costs, optimize resources, and ensure budget compliance throughout the project lifecycle.

What does LOD 300 represent in BIM LOD modeling?

LOD 300 in BIM LOD modeling signifies the design development stage, where model elements have accurate size, shape, location, and orientation. At this level, the model is detailed enough for reliable construction documents, clash detection, and quantity take-offs, but does not yet include fabrication-specific details.

How do LOD 300, LOD 400, and LOD 500 support different project phases?

LOD 300 supports design validation, regulatory checks, and bid preparation.

LOD 400 is used for fabrication, modular construction, and shop drawings.

LOD 500 is essential for facility management and future renovations, or digital twin creation

What is LOD 500, and how is it used in BIM projects?

LOD 500 represents the as-built stage in BIM LOD modeling. The model reflects field-verified conditions and includes comprehensive metadata such as serial numbers, warranties, and maintenance schedules. LOD 500 is primarily used for facility management, operations, and as a foundation for digital twins.