Introduction

Structural engineers have the challenge of capturing existing conditions accurately and integrating them into BIM models that provide a detailed digital representation that guide construction planning. Traditional surveying is slow, prone to human error and doesn’t capture complex geometries. By using reality capture through 3D scanning and converting point cloud data into intelligent BIM models, engineers can reduce discrepancies, speed up design iterations and deliver as-built drawings that match the physical space.

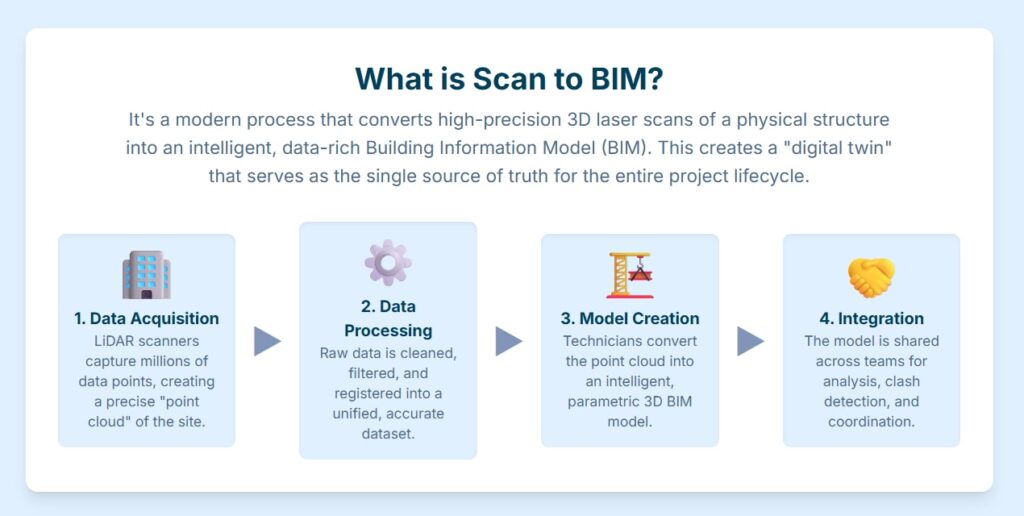

What Is Scan to BIM?

Scan to BIM process is a workflow that combines reality capture technologies – mainly 3D scanning – with Building Information Modelling (BIM) platforms. It involves:

- Capturing Data & Reality Capture: Using tripod-mounted or handheld 3d laser devices, engineers record spatial data in millions of points. This raw data forms the point cloud, representing existing structures, complex buildings, and large and complex projects with both exterior surfaces and interior features.

- Data Processing & Point Cloud Preparation: Specialized modeling software cleans and registers multiple scans into a unified point cloud, ensuring simultaneous localization for accurate alignment. The result: detailed point cloud data ready for reverse engineering.

- Built Model Creation: Through bim modeling services, the point cloud is traced to produce an as-built digital model, capturing existing conditions and existing asset geometries. The resulting 3d model serves as both a detailed record and the basis for further analysis.

- Integration in a Common Data Environment: The BIM model is stored in a common data environment, allowing project stakeholders to collaborate on construction planning, asset management, and design revisions.

The scan to BIM process ensures existing conditions are documented with millimeter precision before design or renovation starts. By converting detailed point cloud data into detailed digital models, engineers get actionable insights for reverse engineering, clash detection and as-built drawings.

Why Scan to BIM Services Is Important for the AEC Industry

The construction industry grapples with unexpected discrepancies between design and reality during construction processes , leading to costly rework and schedule delays. Traditional survey methods—tape measures, total stations—often fall short when construction begins on complex projects or historic buildings. Here’s why scan to bim services are critical:

Accurate Project Planning

Traditional surveys can miss hidden defects or misalignments in complex buildings. With 3D scan to BIM, engineers work off site information, reducing the risk of costly design changes later on.

Seamless Integration

Point cloud data integrates directly into building information modeling platforms (e.g. Autodesk Revit, Bentley AECOsim), enabling scan to BIM workflows where architects, engineers and contractors collaborate in a common data environment.

Historical Preservation

For historic buildings, detailed documentation is key. The Notre Dame de Paris restoration used 50 billion 3D points scanned between 2014-2016 to rebuild the cathedral’s roof and spire using a 3d model digitally.

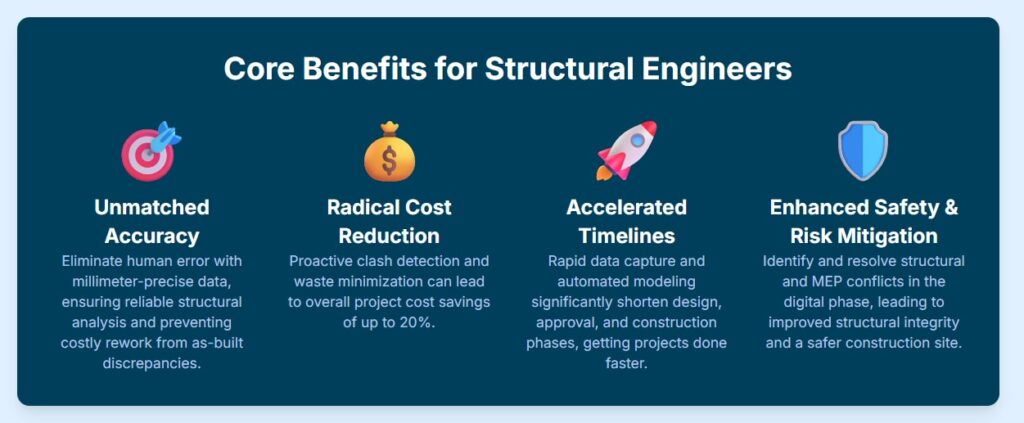

Risk and Cost Control

By injecting precise measurements into accurate bim models and digital twins, stakeholders can forecast clashes, quantify materials and reduce rework, delivering cost and time savings.

How 3D Laser Scanning in Construction Enhances Construction Accuracy

3d laser scanning in construction utilizes advanced modeling tools to elevate accuracy by capturing millions of data points per second, creating an accurate point cloud data record of every surface. Key technical advantages include:

- High-Fidelity Point Cloud Data: Modern terrestrial laser scanners capture millions of points per second, registering surfaces and geometries to within sub–5 mm accuracy.

- Reducing Human Error: Automated scan registration and simultaneous localization eliminate manual tape measurements and subjective judgments.

- Early Clash Detection: When converted into an intelligent BIM model, clashes between structural, mechanical or façade elements appear in the design phase, preventing on-site conflicts.

- Faster Verification: Engineers compare the BIM model against new scan data to verify construction progress, ensuring the built model matches design intent. This has been shown to reduce project delays by over 40% and save more than $75,000 in corrective work costs on case studies.

For large and complex projects, such as stadium renovations or heritage restorations, 3d laser scanning in construction ensure that every irregularity and relevant spatial data is accounted for—critical when tolerances are tight and safety margins minimal.

Key Applications of 3D Scan to BIM Services in Real Projects

- Commercial Retrofits

- Project: Maryland office retrofit.

- Process: Leica scanners captured point cloud data, converted to an LOD 350 BIM model for MEP coordination and structural analysis.

- Outcome: Seamless integration of new systems into existing structures, minimal downtime.

- Residential Renovations

- Project: Arlington Road heritage home.

- Process: Scan to BIM services documented irregular rooflines and historic timber framing. Data fed into Revit for structural reinforcement design.

- Outcome: Zero surprises during demolition; preserved architectural character.

- Institutional Redevelopment

- Project: Montgomery County Police Station upgrade.

- Process: 3D laser scanning captured covert reinforcements and hidden utilities. BIM modeling services provided as-built drawings for facility management.

- Outcome: Improved safety, 65% fewer on-site RFIs.

- Historical Preservation

- Case: Notre Dame de Paris.

- Process: 50 billion points mapped to create a “smart database” to guide the reconstruction of the cathedral’s roof and spire.

- Outcome: Precise restoration matched medieval craftsmanship.

Benefits of Using Scan to BIM in Construction Projects

Precise Measurements & Asset Management

Point cloud data enables intelligent BIM models, a single source of truth for existing building conditions and asset management, ultimately impacting final construction cost .

Better Collaboration & Communication

Share digital models in a common data environment and all project teams and stakeholders – from architects to contractors – have access to the same accurate data, reducing misinterpretation and late-stage RFIs.

Time & Cost Savings

A cost–benefit analysis showed that integrating terrestrial laser scanning with the intelligent software modeling process and BIM delivers positive cash flows, driven by reduced manpower input and faster workflows. No rework and manual re-measurement means overall cost and time savings.

Improved Safety & Risk Management

Scan to BIM projects allow virtual walkthroughs of existing structures, identifying safety hazards (e.g. uncharted voids, deteriorated elements) before site entry, resulting in safer work plans.

Quality Assurance & Compliance

Laser scanning verifies installed building components match design specifications, supporting compliance with standards and codes.

Digital Twins & Asset Management

The BIM scan output becomes the foundation for creating accurate bim models and digital twins, enabling future simulations, energy analysis and proactive maintenance across the building lifecycle.

Summary

3D Scan to BIM closes the gap between the physical world and digital modeling, giving structural engineers accurate point cloud data and robust BIM services. By using the scan to BIM services process, project stakeholders reduce errors, optimize construction planning and unlock long-term value through digital twins and as-built documentation. As laser scanning hardware and intelligent software modeling gets better, the integration of scan to bim reality capture and BIM will become the norm – for more efficient, safer and sustainable projects. 🚀